Do you own a business that produces a lot of waste? If so, a Balex baler could be a good investment for you.

Do you own a business that produces a lot of waste? If so, a Balex baler could be a good investment for you.

Balers are machines that compact waste materials into tight bundles, which make waste storage and transport easier, thereby reducing waste costs. Balex is a superior range of waste balers and in this blog post, we will discuss the many benefits of owning one for waste management.

About Balex

Europress opened its first factory in 1984 and is now based in a modern factory in Kerava, Finland. The company designs and builds waste compactors and balers using cutting edge technology to create their high quality Balex products. They have invested heavily in automation, including a powerful welding robot that allows them to consistently produce their superior waste handling machinery.

As well as manufacturing waste handling equipment, since 1996, Europress has established companies in Sweden, Norway, Estonia and Denmark to allow them to sell and support their Balex products.

Why Choose a Balex Baler?

There are many benefits to choosing a Balex Baler, including:

- Quality

- Safety

- Versatility in waste handling

- Space saving

- Low noise level

- Ease of use

- SMART technology

Quality

Europress is a leading manufacturer of baling machinery, and they invest heavily in automation to produce high quality products efficiently and accurately.

Lasers are used to cut the steel, which allows for a high degree of precision, and welding is performed by robots, providing consistency. Jigs are used to maintain a high degree of accuracy during the build, and the finished baler is shot blasted before painting to prevent corrosion.

Europress’s commitment to quality and efficiency has made them a top choice for businesses looking for baling machinery. Their products are known for their durability and performance, and their investment in automation ensures that their products meet the highest standards.

The mechanical structure of Balex waste balers meets the criteria set by the FEMI strength calculation analysis to ensure that every detail has been considered in producing a durable and working piece of machinery.

Cross cylinder design and solid construction are both features of Balex machinery:

- Cross cylinder design: The long machine stroke ensures stable compression and superior press force to achieve a high bale weight.

- Solid construction: Balex is designed for a long life span of around 6 to 15 years dependant on use and type of waste.

In addition the surface treatment process is designed to be very environmentally friendly and uses a minimal amount of non-recyclable material.

Safety

Europress’s main objective when designing their balers has been to develop a superior quality product that considers and meets both current and future EU safety directives. As a result, the durable, strong build quality of all Balex machinery meets the EN16500 Safety Standards.

EN16500 is a 2015 European safety standard requiring high levels of operational safety for all new vertical balers, including design, manufacture and information for safe usage of the machinery.

Some of the safety features of Balex waste balers include:

- Included in the installation charge is certified staff training for machine operators to ensure they know how to operate the machine safely.

- The heavy duty door closure with electronic sensors ensures safe operation for staff when compacting material or removing bales.

- The balers are key operated as standard giving control over who can operate them.

- The two handed bale ejection system means the operator needs to stand clear of the machine, reducing the risk of injury when the bale is ejected onto a pallet.

- All machinery is designed to provide European compliance and is CE Marked.

Versatility

You will find a product in the range that will meet most waste handling requirements. The machines are suitable for use with a wide range of materials, including cardboard and many types of plastics (shrink wrap, plastic bags, bottles, heavy duty bags, plastic drums, jugs, computer cases, EPS and foam).

The Europress Balex C Waste Baler can bale metals, such as aluminium and food cans, and some machinery in the Balex baler range can bale textiles, clothing and carpet offcuts.

Space saving

The vertical waste balers have a compact footprint and low height. They are heavy duty machines, equipped with cross cylinders for extremely stable compression and allowing a compact low overall height. This gives you a lot of flexibility in where you locate your baler.

The fact that they are able to handle more than one type of waste also gives you a better return on investment in terms of the space allocated to each machine.

Low noise level

These waste balers are very quiet, ensuring a more comfortable environment for the operator as well as those working nearby. As they operate at a very low noise level of only 59dBa, they can be located even in busy working areas.

Easy to use

The Balex range of balers are very easy to use, with many features to make operation simple and efficient. They have a simple and safe operating panel that provides easy to understand instructions for operators using non-language pictograms.

The loading door is also easy to open, with the Turnbuckle closures (strong threaded spindle) ensuring that the main door is opened safely and steadily.

The machines have a large filling opening which means that even larger boxes don’t need to be broken down and the baler can be loaded much faster. Material retainer barbs reduce spring back of the compacted material which allows extra waste to be loaded more quickly. This efficient loading saves time and will therefore save money on labour costs too.

A ‘full light’ comes on when the bale is ready and guarantees consistent bale size without relying on the judgement of the operator. The bale weight is flexible and can be set to produce consistent bales to suit your recycling and transportation needs as well as health and safety requirements. The strap box is at the front of the baler, which makes changing the strap quick and easy. The press plate design saves the operator time by making ‘tie off’ on finished bales easier.

The two handed bale ejection quick and easy. Time is also saved due to the automatic ejection whereby the compressed bale is automatically discharged onto a pallet for easy transportation. The pallet guide ensures that the bale tips into the middle of the Euro pallet.

There are two separate modes of operation for cardboard and plastics and it is easy to switch between the two to allow for optimal use of the baler:

- Mode 1 is most suitable for baling cardboard or material with similar characteristics. The piston returns into the top position immediately after the operating movement in this mode. The device is then ready for feeding immediately afterwards.

- Mode 2 is more suited to baling plastic or material with similar characteristics. The piston remains in the bottom position after the operating movement in this mode. This prevents the material from returning to shape before baling. The operator simply presses the green button to return the piston to the top position before feeding the baler again and it is then ready for the next round.

SMART technology

The intelligent SMART technology used in Europress’s products allows for more efficient, ecological and safe waste handling. This technology has been tested in their baling machinery for several years and a second generation is now being used. It improves durability and safety as well as how easy the machinery is to use.

The technology allows the baler to communicate with and guide the operator throughout use, showing its current state. It also optimises the strokes and pressure and recognises safety risks, guiding the operator in removing them.

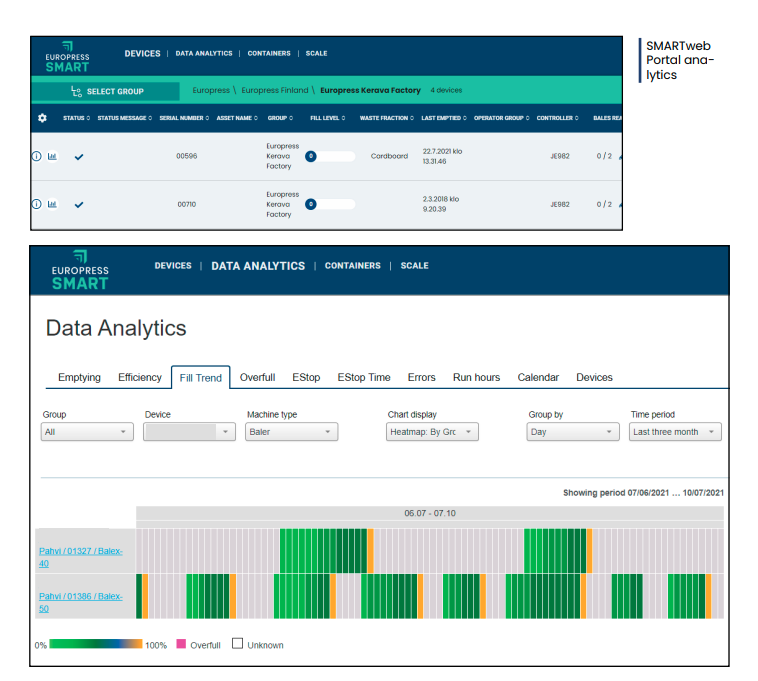

The browser version of the SMART web portal offers real time monitoring and allows you to view and manage your balers with a complete set of analytics, including filling trends, fault history and emptying times. You can also see the number of bales that are ready for collection, making it more efficient for you and your recycler to plan transport.

Types of Balex Balers for Waste Handling

You can find out more about each type of baler by clicking the links below:

- Europress Balex 10 Waste Baler for cardboard and plastic

- Europress Balex 20 Waste Baler for cardboard and plastic

- Europress Balex 30 Waste Baler for cardboard and plastic

- Europress Balex 40 Waste Baler for cardboard and plastic

- Europress Balex 50 Waste Baler for cardboard and plastic

- Europress Balex C Waste Baler for metal waste

All balers in the Balex range come with a two year warranty.

Kenburn was delighted to have been appointed Europress’s very first distributor for the supply of the full range of Balex balers and we continue to be a proud distributor of these products. To find out more about the range and what they can do for your business please contact us and we’ll be happy to help.