Additional Info

Specification

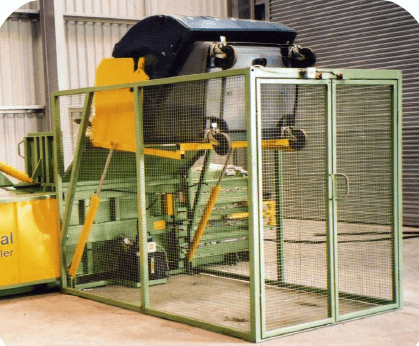

Main Frame: Fabricated mild steel and standard rolled steel sections to form a rigid frame. Bale chamber manufactured to accept strapping machine

Ram Unit: Fabricated mild steel sheet and channel to form a robust frame. Base and top guides fitted with steel wear plates. Top cover provided to prevent material entering machine when ram is moving. Limit switches incorporated to control forward and reverse of the ram travel. Safety switches fitted to feed door(s) to prevent ram moving forward with door(s) open. Rear guard removable to provide ready access for maintenance and cleaning.

Electrical: Programmable logic controller for main system with contactor for main motor drive (15kW). Integral control panel with push buttons for forward, stop and reverse. Ram stops automatically when bale is at the required density – amber flashing light illuminates on semi- automatic models. Photocell sensing commences operating cycle on semi-automatic models. Conveyor contactor and top level photocell can be fitted as an extra in existing control panel. If machines is left idle for three minutes, stand-by mode is automatically initiated.

Feed: Semi-automatic feed hoppers fitted with side access door and photo cell to operate ram cycle. If feed conveyor fitted, the press is equipped with photo sensor to control conveyor feed.

Hydraulic System: System incorporates easily replaceable cartridge air and oil filters. System fully tested prior to delivery. Capacity of oil reservoir: 300 litres.

Strapping: Strapping manually through five slots in the bale chamber while bale is under ram pressure. Bale ties can be steel baling wire, steel strapping or plastic strapping.

Bin feeding: Optional bin feeding system available for applications where material comes from various sources.

Bale size: 1070 x 1000 x 1250mm

Bale weight: approx. 150 – 600 kg depending on material

Ram cycle time: 45 seconds

Throughput: 3 to 4 bales per hour, depending upon material

Note: Floor on which baler is installed must be sound and capable of taking the machine weight (4000kg)

Bale Weights

Polythene: up to approx. 600kg

Cardboard: up to approx. 500kg

Plastic bottles: up to approx. 300kg

Bale weights may vary depending on the condition of the material